TSS ProtecTank has an unique protective material build-up

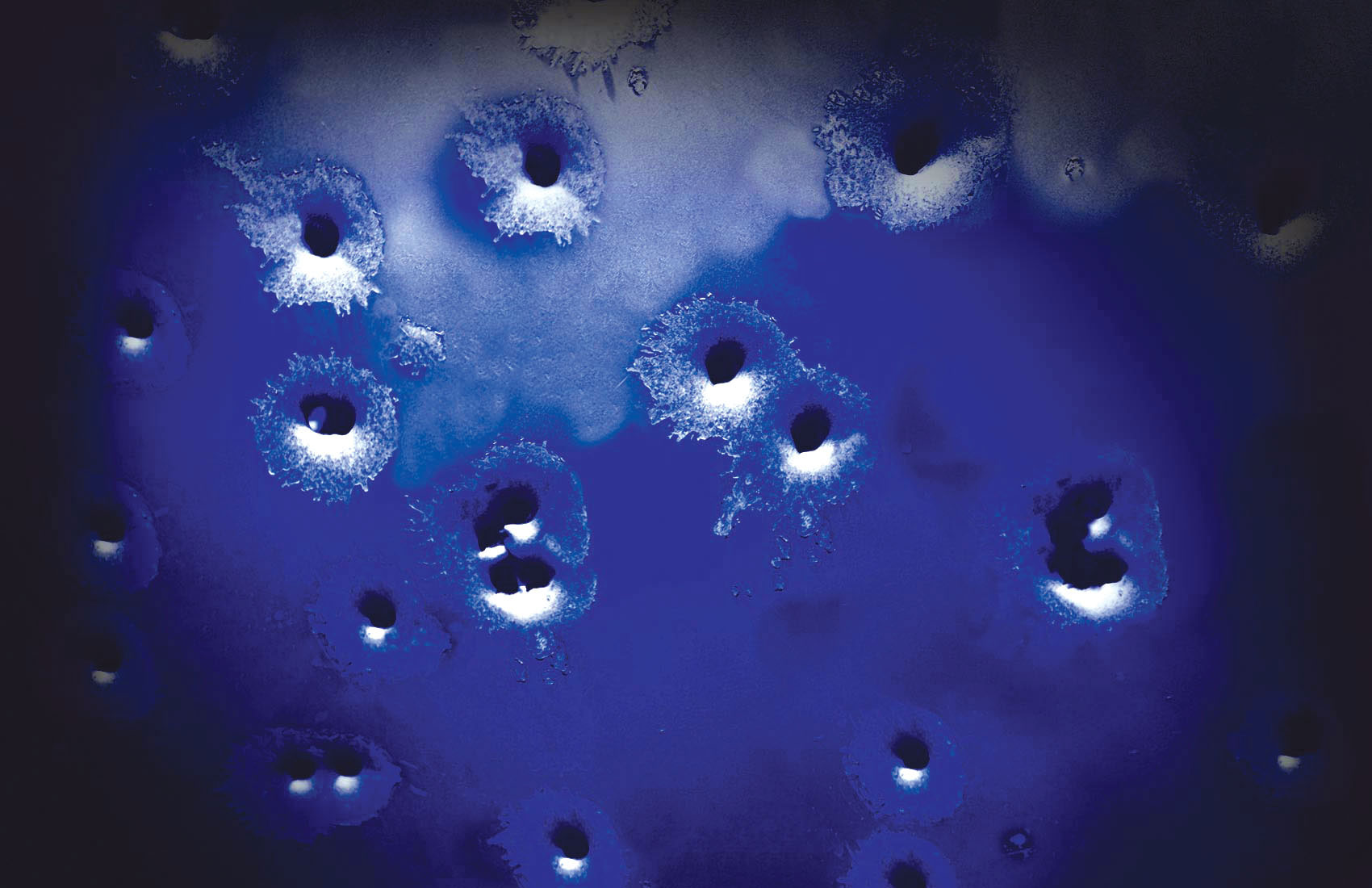

Obviously, the lower the fuel level in the tank, the greater the amount of explosive vapour present when an ignition source occurs (perhaps from a spark). This ignition creates a ‘chain reaction’, as the ignition or ‘flame front’ gets larger and moves faster as it propels through the vapour. The rapid ignition of the flame results in an ever-growing compression wave in front of it, compressing the un-ignited vapour. This is what gives an explosion its power. This sequence occurs in milliseconds.TSS ProtecTank® explosion-suppressant fuel tanks contain a flexible polyurethane (polyether) safety foam with fully open pores, composed of a skeletal network of tiny lightweight interconnecting strands which act as a three dimensional fire screen.

This Safety foam prevents the abovementioned chain reaction from occurring. Instead, vapour ignition is confined to the area immediately around the ignition source. Flame and wave expansion are halted by the foam, which prevents a possibly catastrophic explosion.

With TSS Safety foam fitted in fuel tanks, the danger of explosions caused by gunfire, lightning or electrical ignition is virtually eliminated. TSS Safety foam also reduces the sloshing effect caused by centrifugal forces and de-/acceleration in fuel tanks, and stabilises the fuel in tanks of aircraft, military vehicles, armoured limousines, CIT vehicles, racing cars and boats.

The capacity of the fuel tank is reduced by only 3% of its maximum volume, whilst giving 99% protection from explosions. Filling the fuel tank and distribution of the fuel are not adversely influenced. Instead of retaining fuel, the explosion suppressant Safety foam passes the fuel at a controlled rate predetermined by the size and structure of the strands.

An anti-static, inherently electrically conductive, polyether open cell Safety Foam can be applied according to customer requests or specifications in order to meet USAF military standards MIL-F-87260A.